Machinery Type

“LWC” Density-Weight Control System

Overview

LINKS S.r.l. since more than 30 years can offer an innovative density - weight control apparatus represented, in the latest version, by our LWC system.

This new generation of density weight control is realized by means of an “Intelligent” infra-red ray detector that checks in real time the cotton band while is entering into the converting machine (for zig-zag or cotton rolls) interfaced with a 7” touch screen panel.

According to the thickness and density of the material, this system makes all the necessary calculation and it gives the cutting command to the converting machine in order to have the material in a range of +/- 2% of the nominal weight.

This new generation of density weight control is realized by means of an “Intelligent” infra-red ray detector that checks in real time the cotton band while is entering into the converting machine (for zig-zag or cotton rolls) interfaced with a 7” touch screen panel.

According to the thickness and density of the material, this system makes all the necessary calculation and it gives the cutting command to the converting machine in order to have the material in a range of +/- 2% of the nominal weight.

Available Systems

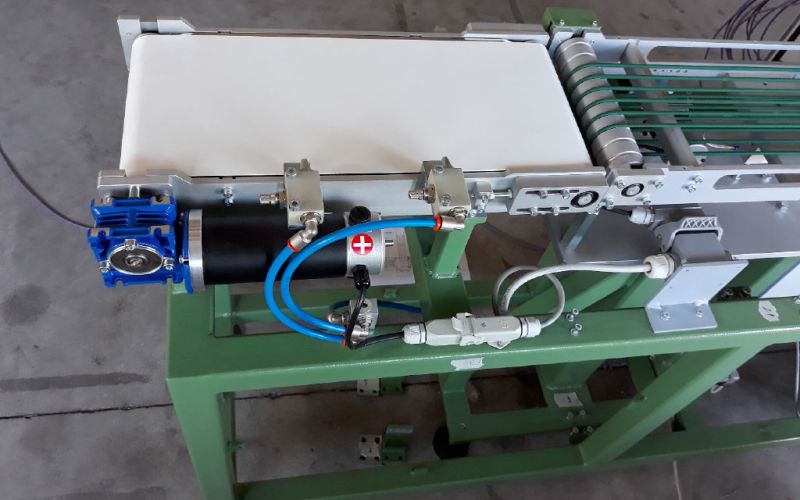

LWC-S INFRA-RED RAY DETECTOR

-

Working width:From 70 to 300 mm. wide cotton band

-

Performance:Up to 85% of the finished products

in +/-2% of the nominal weight

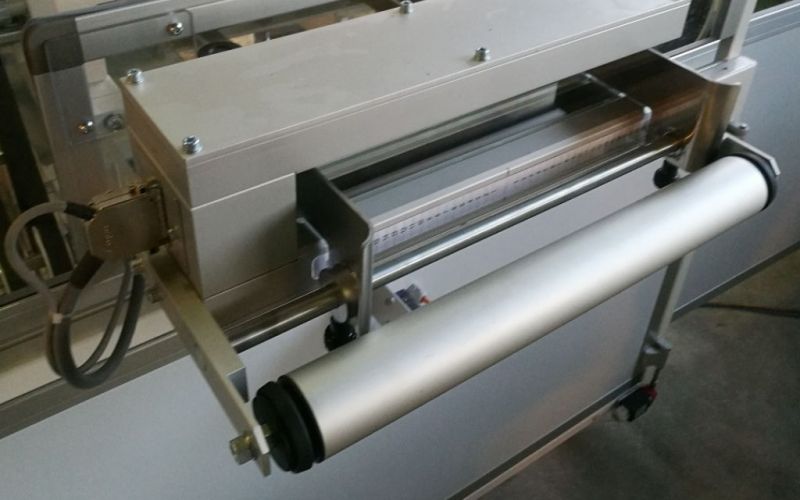

LWC CHECK-WEIGHER

-

It includes the LWC-S detector plus an electronic balance installed at the exit of the converting machine.

This electronic balance checks all the finished products coming out from the machine (zig-zag or rolling machine), shows the real weight on the panel, discharges the under-weight and over-weight products and gives the feedback to the infra-red detector in order to have a complete control of the production process. -

Performance:Same as per LWC-S system

The balance can weigh up to 35 bags/min